SOUNDSCAPE

Interactive digital ceramic design, 2013

Instructor: Jenny Sabin

Cooperative work with Peter Williamson, Karim Daw and Xueting Wei

Design Concept

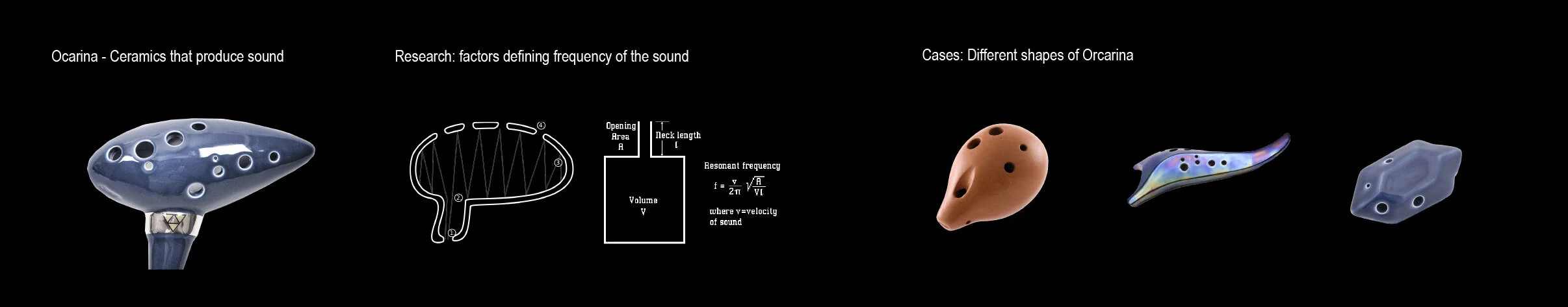

The theme for this ceramic work is about music, or sound. After searching how people made ocarina, a simple instrument that make sound easily, we found that the frequency the wind instrument makes is decided and only decided by its volume and the length of the nozzle, rather than the shape. Adopting this idea ceramics can be potentially developed into an interactive installation of generative forms.

Parameters, constrains and possibilities of ocarina

Process of making an interactive ceramic piece, ocarina prototype

design the form and combination digitally

Left: the final clay vessel, and also the 3D print model; Right: the plaster modes

Postive Molds and Negative Molds

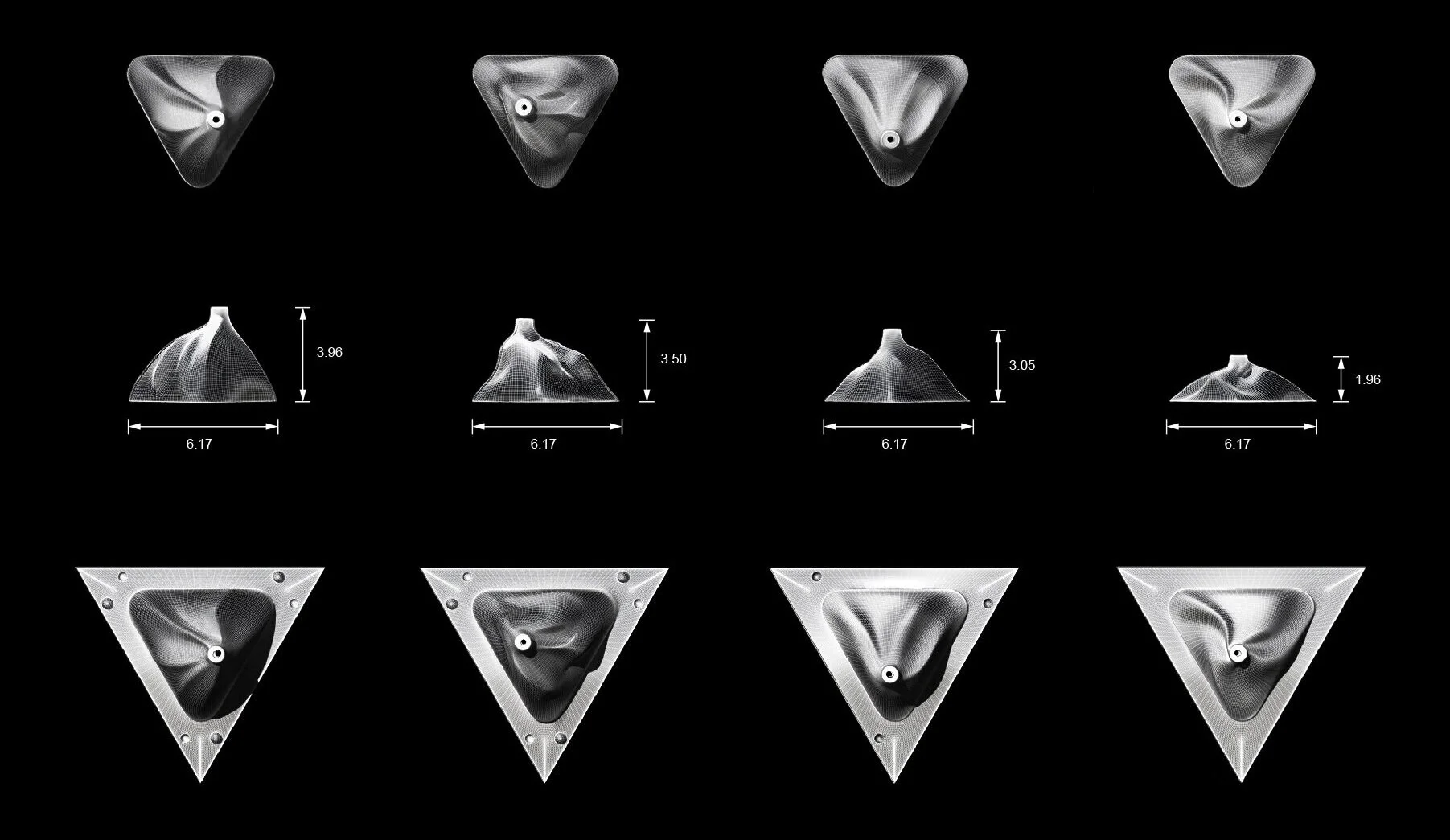

Virtual models are made in Maya for flexibility in control over the geometry, then printed into positive modes. The 3D print models are later casted into negative modes of plaster. The 3D print model has a different mesh resolution than the original virtual model, which becomes a digital texture on the ceramics. The size of the component, 7x7 inches, is a size that in which people can hold the piece comfortably in hand.

3D print models to make the plaster modes, some broke because of the moisture in plaster

Clay components out of plaster modes

The size of the component, 7x7 inches, is a size that in which people can hold the piece comfortably in hand.

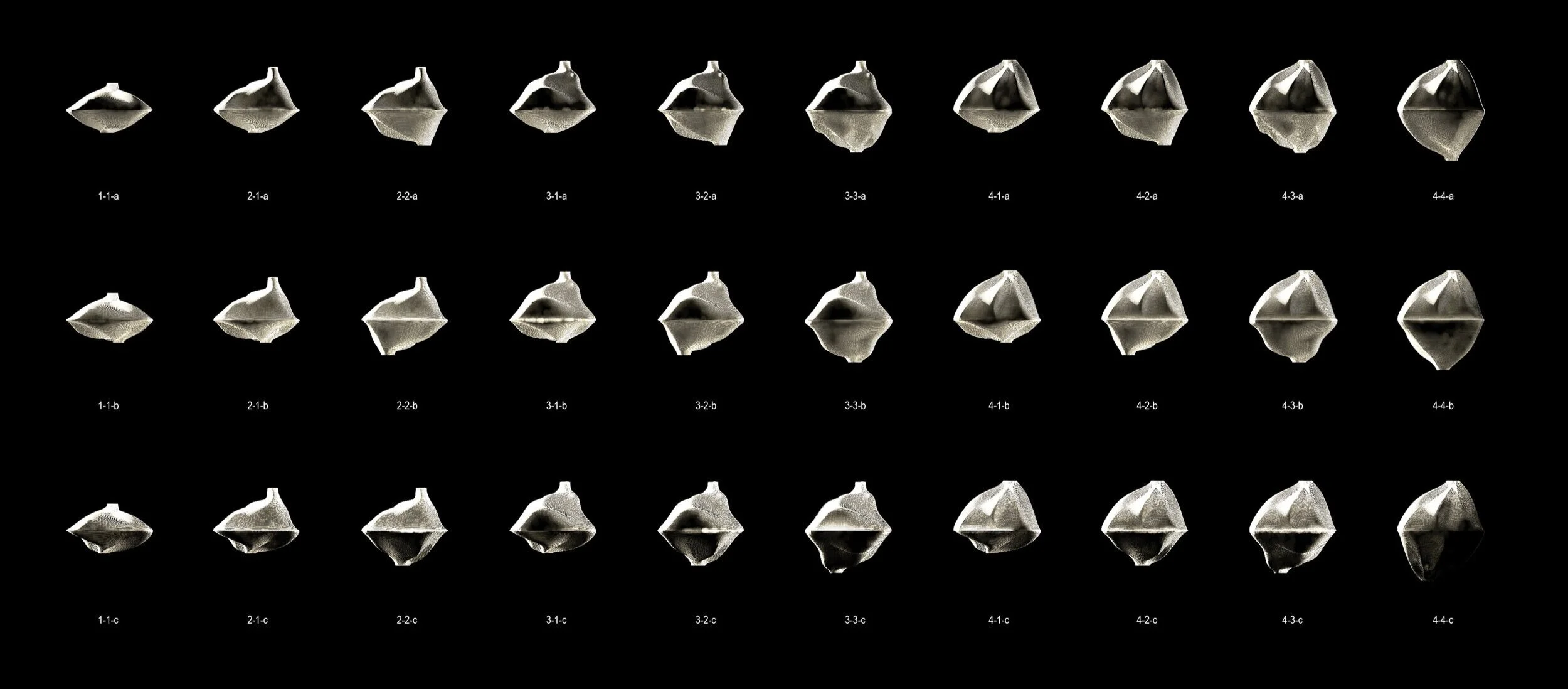

Form Development

Since ceramic is efficient for mass production but inefficient for generative, individual designs, the fabrication strategy is important to the project. Traditionally the origami mode is consisted of two halves of plaster modes; so if the joint section is the same, different modes can still be joint together and produce a complete ceramic piece. As a result, the joint section is equilateral triangle and allow the asymmetrical plaster modes to rotate to 3 different positions during the casting, which means we can multiple the combination by 3 times. Finally, there are 4 modes of different heights and shapes and nozzle positions, with which the total number of combination comes out to be 30.

Generative Molds

Iterations: (Conbination < 2 out of 4 > + 4)*(360/120)=(4*3/2+4)*3=30

Component Famil

Installation

Our component geometry was essentially triangular in section and contained a cable hole at the midpoint of each edge. These cable holes, created to allow the wire dia-grid to pass through the component, were made post-slip casting via a laser cut jig. Furthermore, shrinkage of the ceramics after firing is the major issue, which in our measurements was closer to roughly 8%.

Material

3D print plaster models (positive)

Plaster modes (negative)

White Porcelain Casting Slip - Cone 5

Galvanized Steel Multipurpose Strand Rope, 1 X 7, 1/32” Diameter, 185 Lb Break Strength

Copper Stop Compression Sleeve, For 1/32” Rope Diameter, 1/4” Sleeve Length

Copper Oval Compression Sleeve, For 1/32” Rope Diameter, 1/4” Sleeve Length

Nylon 6/6 General Purpose Flat Washer, Off-white, No. 0 Screw Sz, .18”od, .07”-.09” Thk

Nylon 6/6 General Purpose Flat Washer, Off-white, No. 6 Screw Sz, .44”od, .03”-.05”thk

Open Aluminum Body Turnbuckle, W/zinc-plated Eye & Eye Fittings,5/16”-18 Thread

5/16” White Bumper Post Rings